| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : TYM

Model Number : TYM-W4545

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : Negotiation

Payment Terms : T/T, L/C

Supply Ability : 50 sets per month

Delivery Time : 35 work-days

Packaging Details : seaworthy packing

LSR Injection Molding Machine : Automatic Baby Nipple Manufacturing Machine, LSR Injection Molding Machine

Horizontal : Horizontal LSR injection machine

Useful : LSR machine for Baby nipple

Condition : New

After-sales service provided : Engineers available to service machinery overseas

Style : Horizontal,liquid silicone rubber vertical injection moulding machine

Plastic type : Liquid silicone

Automatic : Fully automatic or manual

Power(w) : 11kw

Machine type : Hydraulic

Key selling points : High-accuracy,Automatic,Multifunctional,Competitive Price,High Productivity

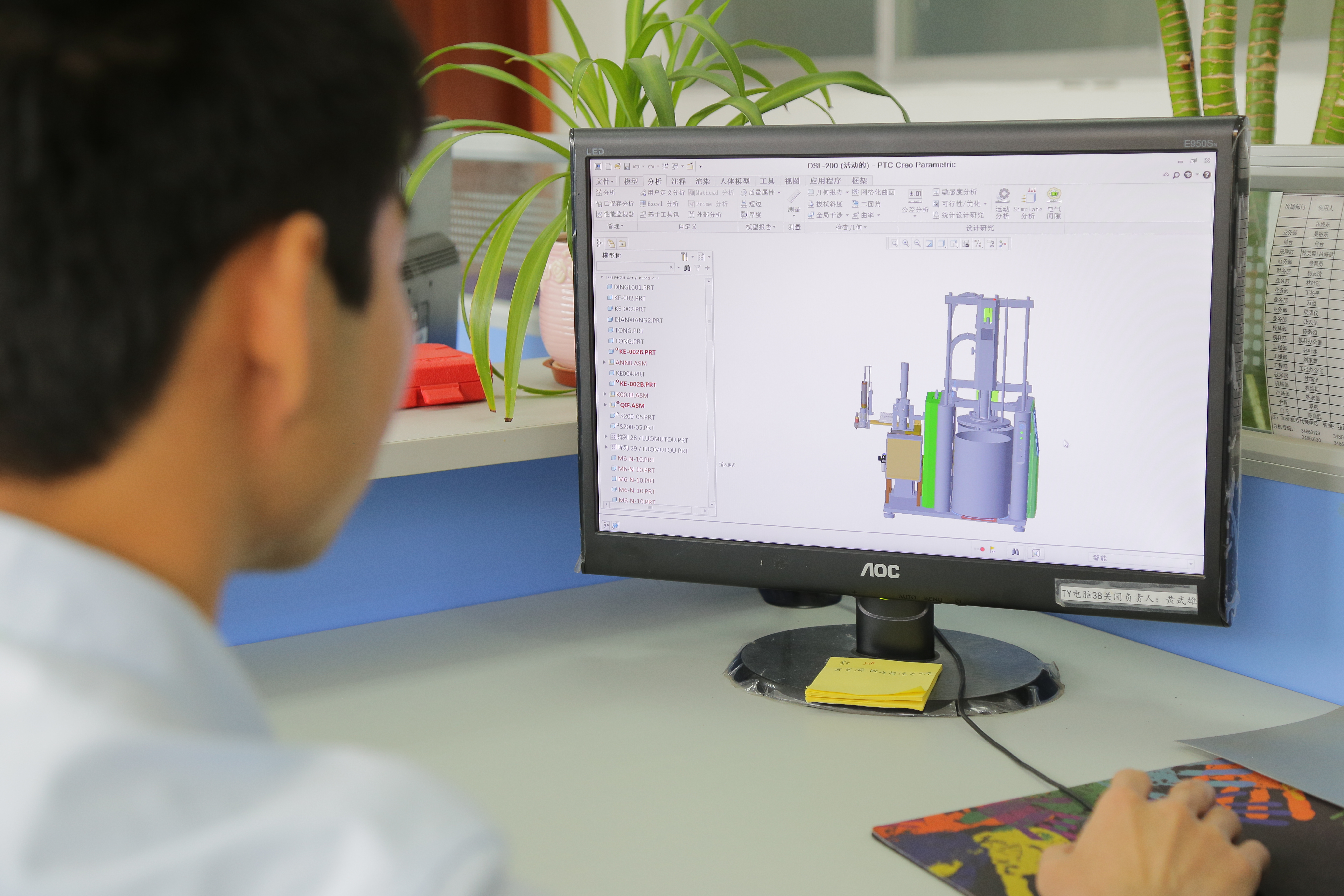

Automatic Baby Nipple Manufacturing Machine, LSR Injection Molding Machine

TYM professional manufacture Automatic Baby Nipple Manufacturing Machine and offer a complete set of Silicone baby production line including LSR injection machine and molds

MECHANICAL PROPERTIES OF LSR

Various grades of silicone rubber have different material properties. This versatility is one of the reasons why LSR is used in so many diverse applications. Whether you require a medical- or food-grade product that offers superior resistance to bacteria, or an automotive component that can withstand excessive heat and vibration, liquid silicone’s mechanical properties make it an excellent starting point.

Key material properties of silicone rubber include its fast curing and low compression set, its resistance to tearing, heat, water and oil, its transparency and electrical conductivity, and its overall strength and long life. You can use LSR at temperatures between -100˚C and 200˚C, expose it to wind, rain and UV light for extended periods of time, or immerse it in water, oil or solvents. The various grades of LSR possess material properties that can stand up to even the most demanding applications.

Mechanical Characteristics for TYM-W4545

| TYM-W4545 Horizontal LSR injection molding machine | |

| Injection Unit | |

| Shot Volume | 165 g |

| Injection Rate | 30 g/s |

| Injection Pressure | 19.6 T |

| Clamping Unit | |

| Clamping Force | 130 T |

| Opening Stroke | 200-700 mm |

| Tie-Bars Space | 450*450mm |

| Ejection Force | 7.8 T |

| Ejection Stroke | 150 mm |

| Others | |

| Pump Pressure | 21 Mpa |

| Motor Power | 11KW |

| Heater Power | 9 KW |

| Mould Orientation Ring Diameter | Φ 100 mm |

| Machine Weight | 5.2T |

| Machine Dimension | 4.0*1.2*2.0 m |

| LSR feeding machine Dimension | 1.2*1.2*2.0m |

Advantage of horizontal injection molding machine:

1,Direct pressure mold opening and closing system. It’s more suitable for producing the LSR parts which can be automatically removed from the mold.

2,Newly-optimized integrated all-in-one design.

3,Meet multiple requirements on the automatic manufacturing technique for LSR products.

4,Shorter the mould closing and opening time,improve the production efficiency.

5,Remote control function.

6,Multi-section mould closing and opening and injection, adjusting speed steplessly.

Advantage of the Machine:

1,TYM processional integrated LSR machine-one control panel computer,more efficient,more energy efficient,save more production cost.

2,The servo system-quick response,high precision,and save 60% more electricity compared to the ordinary motor.

3,The direct pressure injection barrel——high precision,portable and easy to change and clean.

4,Static+dynamic mixer to mix the material and color more thoroughly.

5,TYM series computer controller—parameterized setting, mutigroup electronic ruler to monitor,it can achieve the reliability,stability and precision of machine operation.

6,TYM series L4 number control color slurry pump, computer control color slurry input, accuracy up to 0.01 g, the world leader!

|

|

Horizontal Liquid Silicone Rubber Injection Molding Machine High Accuracy Images |